Table of Contents

- 1. Cloud Adoption and Data Management

- Benefits of Migrating to Cloud-Based Solutions:

- Importance of Data Security and Compliance in the Cloud:

- 2. Industrial Internet of Things (IIoT) and Sensor Integration

- Leveraging IIoT for Real-Time Data Collection:

- Benefits of Sensor Integration:

- 3. Artificial Intelligence (AI) and Machine Learning (ML) in Manufacturing

- Applications of AI and ML:

- 4. Digital Twin Technology

- Benefits of Creating Digital Twins:

- 5. Additive Manufacturing (3D Printing)

- Advantages of 3D Printing:

- 6. Cybersecurity and Data Privacy

- Importance of Robust Cybersecurity Measures:

- 7. Digital Upskilling and Workforce Transformation

- Reskilling and Upskilling the Workforce:

- 8. Digital Customer Experience (CX)

- Utilizing Digital Tools for Improved Customer Service:

- 9. Sustainable Manufacturing Practices

- Leveraging Digital Solutions for Sustainability:

- 10. Supply Chain Digitization

- Enhancing Supply Chain Efficiency:

- Conclusion

Introduction

The winds of change are sweeping through the Indian manufacturing landscape, driven in large part by the increasing adoption of digital technologies. This digital transformation, as it’s called, involves embracing advancements like artificial intelligence, cloud computing, and the Internet of Things (IoT) to fundamentally reshape how you operate. To navigate this evolving landscape and unlock the full potential of digital tools, partnering with a digital marketing agency for manufacturing companies can be a strategic move. These specialists possess the expertise and experience to help you leverage the power of the digital world to reach new audiences, strengthen brand awareness, and ultimately, drive growth.

Why is this important? Well, think of it like this: in today’s globalized world, competition is fierce. To stay ahead of the curve, Indian manufacturers need to be more efficient, productive, and innovative than ever before. Digital transformation is the key to unlocking these benefits and propelling your business towards success.

The good news is, India is waking up to the power of digital. More and more companies are adopting Industry 4.0 and Smart Manufacturing initiatives, which use cutting-edge technologies to automate processes, optimize production, and gain valuable insights from data.

Ready to join the digital revolution? Let’s dive into the Top 10 Digital Transformation Initiatives that can transform your Indian manufacturing company:

1. Cloud Adoption and Data Management

Benefits of Migrating to Cloud-Based Solutions:

- Scalability: Cloud-based solutions, such as Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM), allow manufacturers to scale their operations seamlessly.

- Cost Efficiency: By eliminating the need for on-premises infrastructure, companies can reduce costs significantly.

- Flexibility: Cloud platforms enable remote access, facilitating collaboration across geographies.

Importance of Data Security and Compliance in the Cloud:

- Data Protection: Manufacturers must prioritize data security to safeguard sensitive information.

- Compliance: Adhering to regulations (like GDPR) ensures ethical data handling.

- Statistics: According to a survey by Deloitte, 78% of Indian manufacturers consider data security a top priority.

2. Industrial Internet of Things (IIoT) and Sensor Integration

Leveraging IIoT for Real-Time Data Collection:

- Connected Devices: IIoT enables sensors and devices to collect real-time data from machinery, production lines, and supply chains.

- Predictive Maintenance: Sensors detect anomalies, preventing breakdowns and reducing downtime.

- Statistics: The global IIoT market is projected to reach $310 billion by 2023.

Benefits of Sensor Integration:

- Process Optimization: Sensors provide insights into production efficiency, energy consumption, and quality control.

- Supply Chain Visibility: Tracking goods in transit improves logistics and reduces delays.

3. Artificial Intelligence (AI) and Machine Learning (ML) in Manufacturing

Applications of AI and ML:

- Production Planning: AI optimizes production schedules, minimizing waste and maximizing output.

- Quality Control: ML algorithms detect defects and ensure product consistency.

- Smart Robots: AI-powered robots automate tasks, enhancing efficiency.

- Statistics: The Indian AI market is expected to grow at a CAGR of 33.49% from 2021 to 2026.

4. Digital Twin Technology

Benefits of Creating Digital Twins:

- Process Simulation: Digital twins allow manufacturers to simulate processes, identify bottlenecks, and optimize workflows.

- Remote Monitoring: Real-time monitoring of physical assets improves maintenance efficiency.

- Applications: Automotive companies use digital twins for vehicle design and testing.

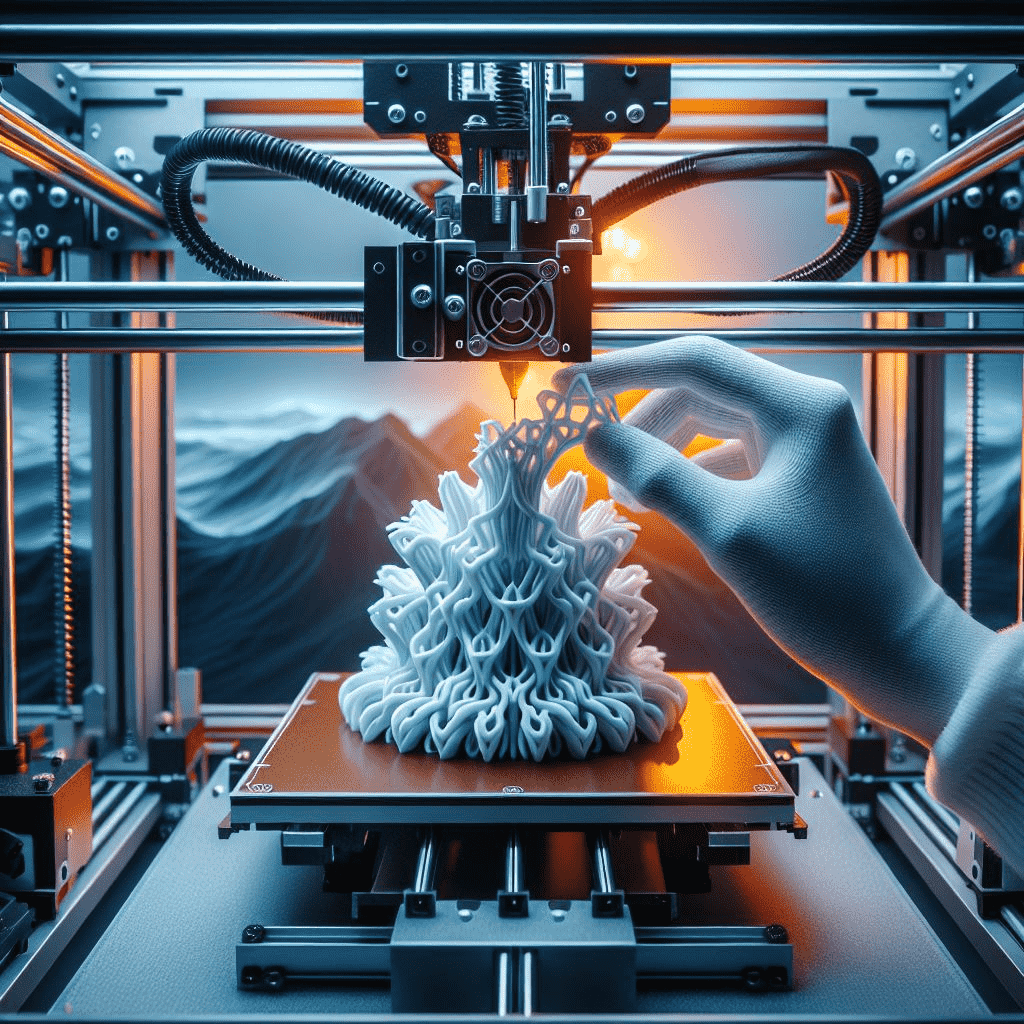

5. Additive Manufacturing (3D Printing)

Advantages of 3D Printing:

- Prototyping: Rapid prototyping reduces development time and costs.

- Customization: 3D printing allows personalized products.

- Supply Chain Agility: On-demand production minimizes inventory.

- Statistics: The global 3D printing market is estimated to reach $34.8 billion by 2024.

6. Cybersecurity and Data Privacy

Importance of Robust Cybersecurity Measures:

- Threat Landscape: Cyberattacks can disrupt production and compromise sensitive data.

- Protective Measures: Firewalls, encryption, and employee training are essential.

- Compliance: Manufacturers must comply with data protection regulations.

- Search Term: “Cybersecurity in Indian Manufacturing.”

7. Digital Upskilling and Workforce Transformation

Reskilling and Upskilling the Workforce:

- Technology Adoption: Training employees in digital tools ensures smooth transitions.

- Continuous Learning: Fostering a culture of innovation and adaptability.

- Statistics: 90% of Indian manufacturers believe upskilling is crucial for digital transformation.

8. Digital Customer Experience (CX)

Utilizing Digital Tools for Improved Customer Service:

- Online Sales Channels: E-commerce platforms enhance customer reach.

- Personalization: AI-driven recommendations improve customer experience.

- Statistics: 70% of Indian consumers expect personalized experiences.

9. Sustainable Manufacturing Practices

Leveraging Digital Solutions for Sustainability:

- Energy Efficiency: IoT and AI optimize energy consumption.

- Waste Reduction: 3D printing minimizes material waste.

- Role of Digital Transformation: Aids in achieving environmental goals.

10. Supply Chain Digitization

Enhancing Supply Chain Efficiency:

- Real-Time Visibility: Digital tools track inventory, shipments, and demand.

- Collaboration: Cloud-based platforms facilitate communication with suppliers.

- Statistics: 80% of Indian manufacturers plan to invest in India

Conclusion

In conclusion, the digital transformation landscape in Indian manufacturing is rapidly evolving. Companies are embracing cloud solutions, integrating sensors for real-time data, and leveraging AI and ML for smarter decision-making. The journey toward sustainable practices, upskilling the workforce, and enhancing customer experiences is essential for staying competitive in today’s dynamic market. As India continues to innovate, these initiatives will shape the future of manufacturing, driving efficiency, resilience, and growth.